– Finishing touches –

Don’t make the mistake of thinking that the creative process for your product comes to an end when you choose the right bottle shape. Quite the opposite: the final polish and all those little extra details influence your product’s image at least to the same extent as the shape itself. Today’s clients are interested in attention to detail – and that’s why it is essential to prove that you have an eye for it.

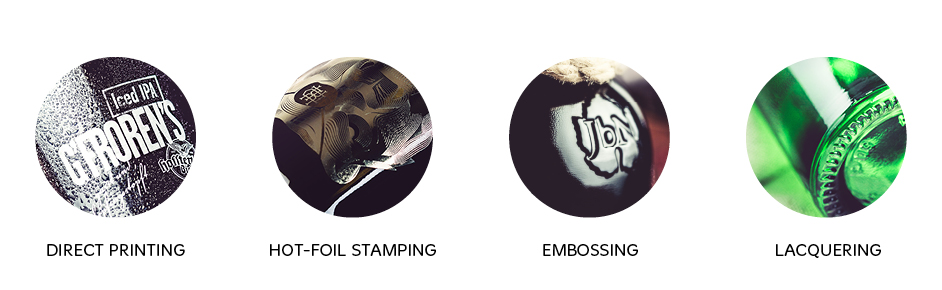

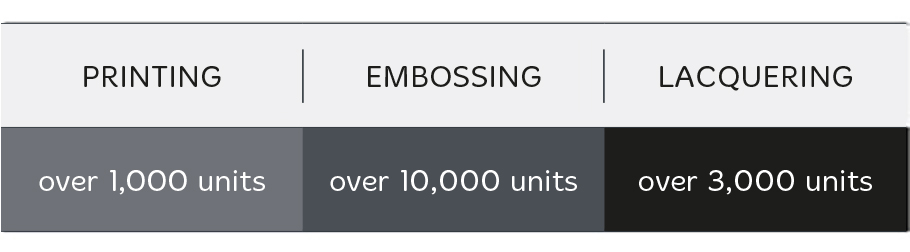

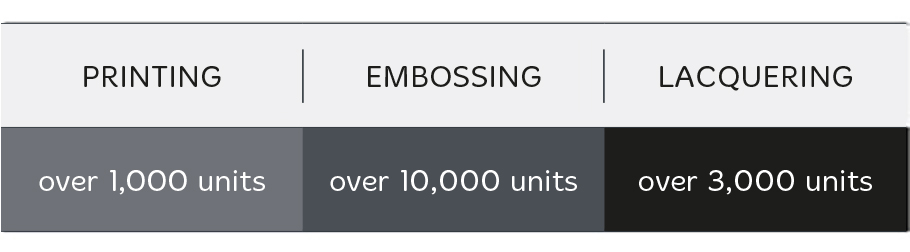

Finishing the bottles may take the form of embossing, direct printing, lacquering in an infinite array of colours and textures, as well as, of course, foliation or sleeving. There are no limits to your creativity: we can usually turn your visions into reality. All you have to do is ask and we’ll let you know one way or the other. On the subject of finishing, it’s important to understand that we are talking about an additional step that is not usually carried out by the glassworks or factory where our bottles come from. In this respect, a finishing process will naturally extend the length of our design process.

Our utmost priority is to achieve the ideal result, working in close collaboration with you. And sure enough this will involve tests and trial prints or attempts at lacquering and sample foliations – for as long as it takes until we get the right result. Only then will we start serial production and document the special settings of the finishing process in detail. This will enable us to make absolutely sure that we can reproduce the exact same result even after x number of test runs. It is precisely this dedication that carries you a step above the competition. Together we will put together an optical masterpiece a unique product – in short, something wonderfully special.

A small stepto perfection

We give you all the options.

Stand-alone colours, lacquering, foiling, direct printing processes, closures – whatever you need to individualise and personalise your product. In small quantities too. That's our promise.

See for yourself.

DIRECT PRINTING

Labels are old hat. So old that even the ancient Sumerians were adorning various vessels with them over 6,000 years ago. We offer a modern alternative which is superior to the customary static bottle labels in almost every respect: direct printing.

Using screen printing we can immortalise any motif or colour tone directly on the glass surface of your packaging. In so-called "ceramic screen printing", the graphics are burned into the bottle at a temperature of 650 degrees. The possibilities are endless – every bottle can be printed on practically anywhere using 360 degree pressure. In addition, the printing process is very reasonably priced. Direct printing is particularly recommended for bottles that have to survive long storage times. These high-quality decorations can't wear down or fade and are plainly attention-grabbing. Your product will always look like new.

Reference: Brauerei Hofstetten

DIRECT PRINTING

Labels are old hat. So old that even the ancient Sumerians were adorning various vessels with them over 6,000 years ago. We offer a modern alternative which is superior to the customary static bottle labels in almost every respect: direct printing.

Using screen printing we can immortalise any motif or colour tone directly on the glass surface of your packaging. In so-called "ceramic screen printing", the graphics are burned into the bottle at a temperature of 650 degrees. The possibilities are endless – every bottle can be printed on practically anywhere using 360 degree pressure. In addition, the printing process is very reasonably priced. Direct printing is particularly recommended for bottles that have to survive long storage times. These high-quality decorations can't wear down or fade and are plainly attention-grabbing. Your product will always look like new.

Reference: Brauerei Hofstetten

HOT-FOIL STAMPING

What sounds merely like "ironing film" onto a surface – similar to what we see with T-shirt printing – is actually a very innovative and technically challenging finishing process. The potential effects can be rather unexpected, particularly on glass, creating some really eye-catching stuff. We always use hot-foil stamping whenever we want to accentuate a particular design feature or enhance lettering in the overall design. You can achieve any look you want - extravagant or understated - depending on how the hot-foil stamping is applied.

The process requires three components: a carrier material (in our case our glass bottles), a (mostly metallic) film and an embossed stamp corresponding to the lettering or design feature. The embossed stamp or embossing roller (depending on the size of the design) are warmed to temperatures of between 80 and 220 degrees Celsius. Then the film i.e. colour or metallic particles are transferred onto the glass through the raised areas on the embossing roller. A so-called transfer layer on the hot foil ensures a

strong bond with the glass.

It's important to note that not every hot foil works the same way or gives you the same effect. For this reason you also need

a variety of embossing processes. In technical jargon we refer to this as: flat - flat, round - flat or even round - round. This mechanical versatility ensures enormous flexibility in implementation: relief embossing, deep embossing, structure embossing, flat embossing (coin embossing)... there are virtually no bounds to creativity thanks to this process.

However, there is a limit to variety:

material composition and the shape of the containers may cause problems. And not every

foil colour is available in all film qualities for all materials. But that's

what we're here for - this is our specialist field. We look forward to

receiving your questions about this wonderful finishing technique.

Reference: Blind Tiger Gin

HOT-FOIL STAMPING

What sounds merely like "ironing film" onto a surface – similar to what we see with T-shirt printing – is actually a very innovative and technically challenging finishing process. The potential effects can be rather unexpected, particularly on glass, creating some really eye-catching stuff. We always use hot-foil stamping whenever we want to accentuate a particular design feature or enhance lettering in the overall design. You can achieve any look you want - extravagant or understated - depending on how the hot-foil stamping is applied.

The process requires three components: a carrier material (in our case our glass bottles), a (mostly metallic) film and an embossed stamp corresponding to the lettering or design feature. The embossed stamp or embossing roller (depending on the size of the design) are warmed to temperatures of between 80 and 220 degrees Celsius. Then the film i.e. colour or metallic particles are transferred onto the glass through the raised areas on the embossing roller. A so-called transfer layer on the hot foil ensures a

strong bond with the glass.

It's important to note that not every hot foil works the same way or gives you the same effect. For this reason you also need

a variety of embossing processes. In technical jargon we refer to this as: flat - flat, round - flat or even round - round. This mechanical versatility ensures enormous flexibility in implementation: relief embossing, deep embossing, structure embossing, flat embossing (coin embossing)... there are virtually no bounds to creativity thanks to this process.

However, there is a limit to variety:

material composition and the shape of the containers may cause problems. And not every

foil colour is available in all film qualities for all materials. But that's

what we're here for - this is our specialist field. We look forward to

receiving your questions about this wonderful finishing technique.

Reference: Blind Tiger Gin

EMBOSSING

Give your product individuality. DEmbossing not only enhances the look the your glass bottle it also appeals to another of your senses: touch. By embossing the glass surface, we can playfully add some lettering, a logo or some other graphic element to your glass bottle. These stand out distinctly from other surfaces; not only do they look outstanding, they also give it the magic touch.

In addition to messages or logos, it is also possible to give the entire bottle a pattern. The bottle base too can be given a signature or a symbol. Embossing is a great way to transform your product into an iconic eye-catcher and position it on the market with a great packaging idea. An embossed bottle will leave a lasting impression in the truest sense of the word.

Reference: JBN Jägersberger

EMBOSSING

Give your product individuality. DEmbossing not only enhances the look the your glass bottle it also appeals to another of your senses: touch. By embossing the glass surface, we can playfully add some lettering, a logo or some other graphic element to your glass bottle. These stand out distinctly from other surfaces; not only do they look outstanding, they also give it the magic touch.

In addition to messages or logos, it is also possible to give the entire bottle a pattern. The bottle base too can be given a signature or a symbol. Embossing is a great way to transform your product into an iconic eye-catcher and position it on the market with a great packaging idea. An embossed bottle will leave a lasting impression in the truest sense of the word.

Reference: JBN Jägersberger

LACQUERING

In most supermarkets, dull conformity reigns on the wine, beer and juice bottle shelves. Most glass bottles won't deviate from the usual basic colours, and most producers don't seem to dare selecting a colour outside of the norm. But there's a lot to be said for doing so.

We can lacquer your bottles in any conceivable colour. Even unusual colours such as pink or bright red aren't an issue. These uncommon shades catch the eye immediately on any shelf and spark the consumer's curiosity. Of course, less conspicuous colours and pale tints are possible as well. Thanks to our modern lacquering facility we can incorporate your product's bottle colour into the creative process and tailor it perfectly to the content. You choose the type of lacquering - anything is possible, whether gloss, matte, opaque or transparent - even dual-colour printing.

Reference: Destillerie Keckeis

LACQUERING

In most supermarkets, dull conformity reigns on the wine, beer and juice bottle shelves. Most glass bottles won't deviate from the usual basic colours, and most producers don't seem to dare selecting a colour outside of the norm. But there's a lot to be said for doing so.

We can lacquer your bottles in any conceivable colour. Even unusual colours such as pink or bright red aren't an issue. These uncommon shades catch the eye immediately on any shelf and spark the consumer's curiosity. Of course, less conspicuous colours and pale tints are possible as well. Thanks to our modern lacquering facility we can incorporate your product's bottle colour into the creative process and tailor it perfectly to the content. You choose the type of lacquering - anything is possible, whether gloss, matte, opaque or transparent - even dual-colour printing.

Reference: Destillerie Keckeis